triGEL - freeze clamping – clamping with ice

- Ideal for bulky parts

- Quick freezing and thawing times

- Very high adhesion

- Also suited for non-metal parts

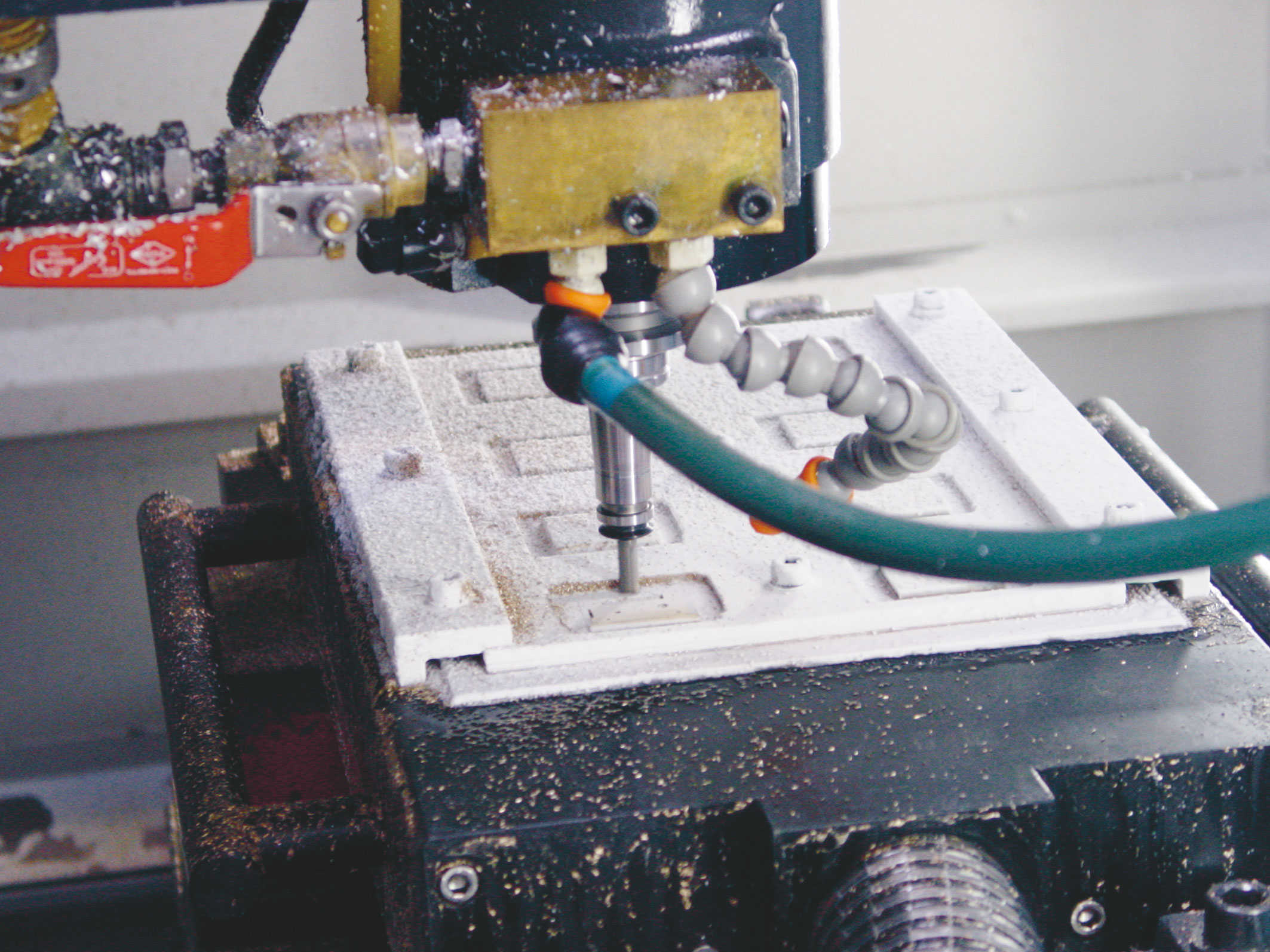

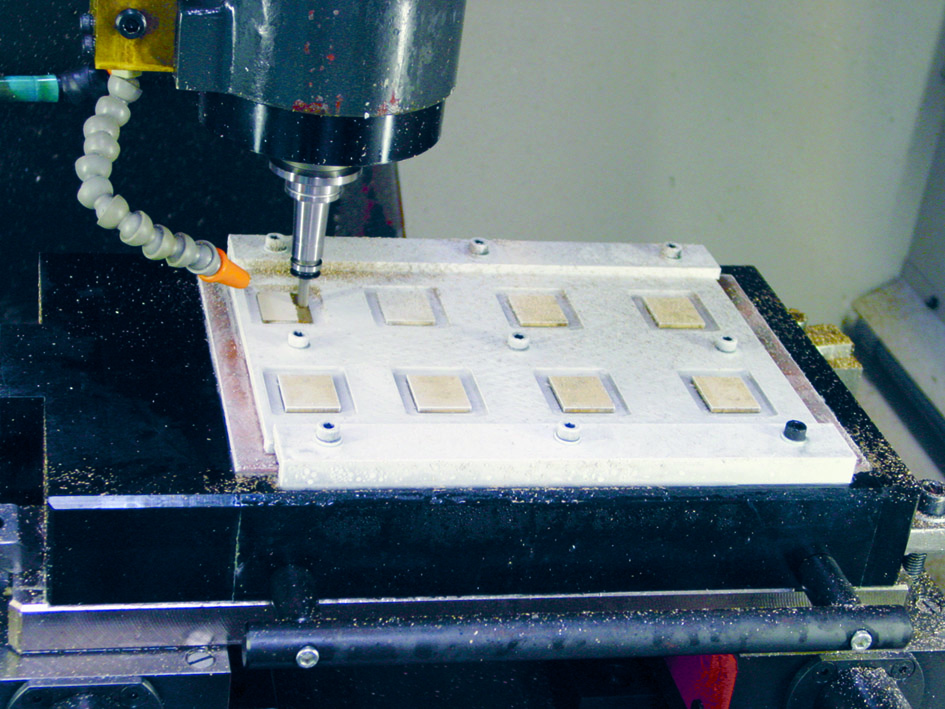

Freeze clamping is a clamping technique that is primarily used for bulky parts made of metal, most mineral materials as well as plastic. Ice offers excellent adhesion. When using the triGEL system, cold gas is run through the work table’s labyrinth of cables and cooled to the working temperature of minus 8 degrees Celsius. The workpieces and the work table are coated with a fine water film, which clamps the parts in place after freezing in approximately 60 seconds. The process is reversed to loosen the workpieces. The device functions as heating pump. It allows the thawing point to be reached quickly, which releases the workpieces.

With 2 N/mm2, the adhesive force is 10 to 20 times greater than that of vacuum clamping. However, the tolerance for strong, mechanical shocks is smaller. triGEL consists of a connected control box and work table. The standard table sizes are: 100 x 100 mm, 100 x 200 mm, 200 x 400 mm, 170 x 450 mm and 500 x 550 mm.